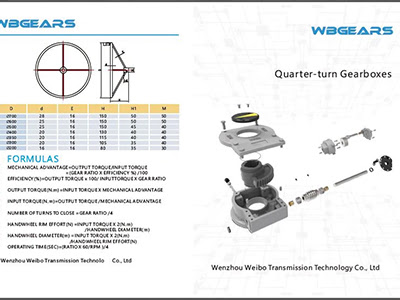

New Business About Gearbox

Our company has launched a new business about gearbox recently. Attached files are the main information of our gearbox. (Including sample, ISO certificate etc.) If you are interested or need it, please contact me directly. I am looking forward to your reply in time.

Workshop Overview-producing Open Type Ball Valves

On the second floor, we just opened an area for producing open type ball valves recently. The pictures below are only for reference. These information and photos are part of our latest situation, if you want to know more details, please contact me directly. (You can call me Yulia, my email is yulia@outong-group.com.)

Our Laboratory

And our lab is near the A-area, and there is some test equipment in the photo. If you want to know more, you can contact me directly by email. My email is yulia@outong-group.com.

Workshop Overview

On the first floor, there are total 6 areas at the scene of the workshop; respectively are A-area, B-area, C-area, D-area, E-area, F-area. Also, every area has its own duty, such as machining, inspecting etc. The photos as below:

The Latest Situation Of Our New Factory

This factory is our new one of company, and it’s usually called ”new factory”.The following is a picture of the entrance of our workshop and the interior of the workshop. This is part of our latest situation. If you want to know more details, please contact me directly. (You can call me Yulia, my email is yulia@outong-group.com.)

The Site Construction Of Russian Komsomolsk Oil Refinery

The site construction of Russian Komsomolsk oil refinery On November 20th, our manager of foreign trade department called hawk xia went to Russia to attend the technical study and discussion meeting of a project. Please refer to the following pictures for details.

There Are Our Latest Ball Valves In Our Factory

full welded ball valve(blue),3-piece forged steel fixed ball valve(yellow)

Application Range Of Fixed Ball Valve

Fixed ball valve is suitable for class150~class1500, pn16~pn100, JIS 10k~jis 20K of various pipe roads, applicable temperature:-196~350℃, used to truncate or connect the media in the pipeline, the selection of different materials, can be applied to the transport of water, steam, oil, Nitric acid, acetic acid, oxidizing medium, urea, etc., are widely used in petroleum refining, long-distance pipeline, chemical industry, paper, Pharmaceutical, water conservancy, electricity, municipal, steel and other fields. Fixed ball valve Drive mode for worm gear drive, manual, pneumatic or electric. Fixed ball valve generally uses flange connection, can also be used for welding connection.

Function Of Fixed Ball Valve

1, double blocking and discharge function: Fixed ball valve using spring pre-tightening floating seat, regardless of the valve in the open or full off state, the upper and lower side of the seat so that the fluid block, valve body cavity retention through the discharge valve excretion. 2, Automatic pressure relief function: valve body cavity stay medium temperature rise and cause abnormal boost, do not need to pass the safety valve, and only by the seat function can automatically release pressure, which is very important to ensure the safety of the valve in the delivery of liquid media. 3, fire safety structure: valves are equipped with fire safety functions, its design, manufacture are in accordance with API 607 and API 6FA specification requirements.

Plug Valve

The plug valve is a closing or plunger-shaped rotary valve that opens or closes by opening or closing the passage opening on the valve plug to the passage opening on the valve body by rotating 90 degrees. Its valve plug can be cylindrical or conical in shape. In a cylindrical valve plug, the passage is generally rectangular; in a tapered valve plug, the passage is trapezoidal. These shapes make the structure of the plug valve light. It is most suitable for use as a cutting and closing medium and a shunt, but it can also be used for throttling depending on the applicable properties and the erosion resistance of the sealing surface. A plug body with a through hole is used as a valve for the opening and closing member. The plug body rotates with the valve stem to achieve the opening and closing action. Small, non-filled plug valves are also known as "Cock". The plug body of the plug valve is mostly a cone (also has a cylinder), and cooperates with the conical hole surface of the valve body to form a seal pair. The plug valve is the earliest type of valve, which has a simple structure, quick switch and low fluid resistance. The ordinary plug valve is sealed by the direct contact between the finished metal plug body and the valve body, so the sealing performance is poor, the opening and closing force is large, and it is easy to wear, and can usually only be used for low pressure (not higher than 1 MPa) and small. Caliber (less than 100 mm).

Ball Valve Repair Skills

1. It is necessary to first find out that the upper and lower pipelines of the ball valve have been relieved of pressure before they can be disassembled and disassembled. 2. Care must be taken to prevent the sealing surface of the damaged part during decomposition and reassembly, especially for non-metallic parts. Special tools should be used when removing the O-ring. 3. The bolts on the flange must be tightened symmetrically, gradually and evenly during assembly. 4. The cleaning agent should be compatible with the rubber parts, plastic parts, metal parts and working medium (such as gas) in the ball valve. When the working medium is gas, the metal parts can be cleaned with gasoline. Non-metallic parts are cleaned with purified water or alcohol. 5. The individual parts that are broken down can be cleaned by dipping. Metal parts that have been left undecomposed by non-metallic parts can be scrubbed with a clean, fine cloth impregnated with a cleaning agent (to prevent the fibers from falling off and sticking to the parts). When cleaning, remove all grease, dirt, glue, dust, etc. that adhere to the wall. 6. Non-metallic parts should be taken out of the cleaning agent immediately after cleaning. Do not soak for a long time. 7. After cleaning, it needs to be assembled after the wall cleaning agent is volatilized (can be wiped with silk cloth without dipping cleaning agent), but it should not be left for a long time, otherwise it will rust and be polluted by dust. 8. New parts should also be cleaned before assembly. 9. Lubricate with grease. Grease should be compatible with ball valve metal materials, rubber parts, plastic parts and working media. When the working medium is gas, for example, special 221 grease can be used. Apply a thin layer of grease to the surface of the seal mounting groove, apply a thin layer of grease to the rubber seal, and apply a thin layer of grease to the sealing surface and friction surface of the stem. 10. Metal debris, fibers, grease (except for the specified use) should not be allowed to be contaminated, adhered or stuck on the surface of the part or enter the inner cavity.

Basic Description Of Fixed Ball Valve

Fixed ball valve, is a new generation of high-performance ball valve, suitable for long-distance pipeline and general industrial pipelines, its strength, safety, resistance to harsh environment and so on in the design of special considerations, suitable for a variety of corrosive and non-corrosive media. Compared with the floating ball valve, when working, the valve front fluid pressure on the sphere to produce all the force passed to the bearing, will not make the sphere to the seat, so the seat will not withstand excessive pressure, so fixed ball valve torque is small, seat deformation is small, sealing performance is stable, long service life, suitable for high pressure, large caliber occasions. Advanced Spring pre-seat assembly with self-tightening characteristics for upstream sealing. Each valve has two seats, each direction can be sealed, so the installation has no flow limit, is bidirectional. This valve is generally installed horizontally. Fixed ball valve has two block and three block type two valve body structure, the middle flange with bolt connection, seal using reinforced PTFE inserted into the stainless steel coil, the rear of the steel ring with a spring to ensure that the seat close to the sphere, keep the seal. The upper and lower stem are equipped with PTFE bearings, reducing friction, operating labor-saving, the bottom of the small shaft with adjustment sheet, to ensure that the ball and seal ring connection position. Full path: Valve flow aperture is consistent with the diameter of the pipeline for pipeline cleaning.